Cov khoom sib xyaw

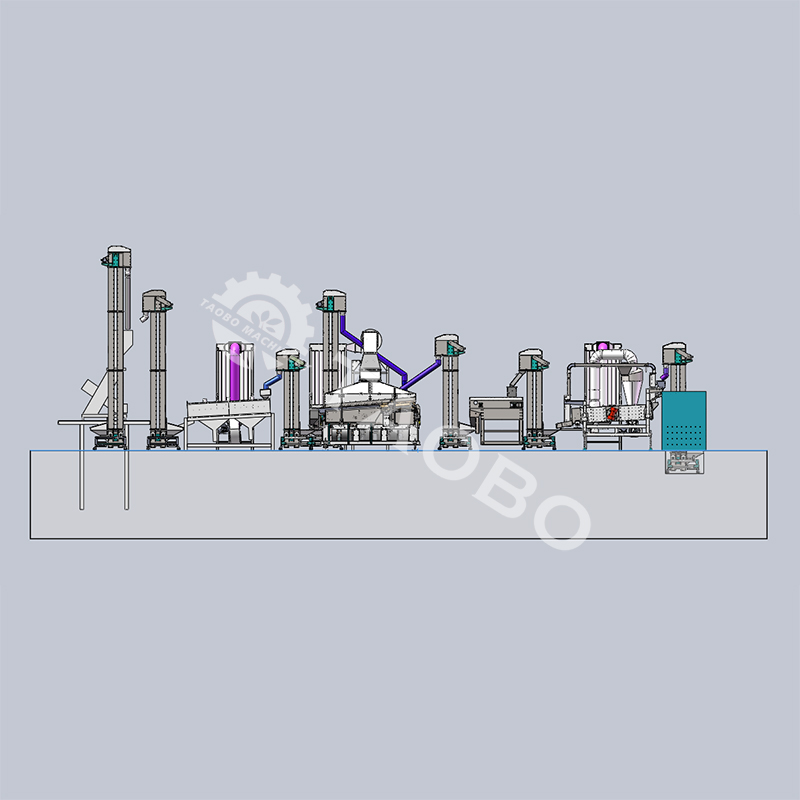

Sib nqus separator, tshwj xeeb lub ntiajteb txawj nqus destoner, tshwj xeeb lub ntiajteb txawj nqus xaiv tshuab, polishing tshuab, vibrating taum ntxuav ntau lawm kab muaj cov cua tshuaj ntsuam xyuas tshuab, grading screen, ntau ntim scale, mem tes plua plav collector, hnab plua plav collector, elevator thiab lwm yam auxiliary cov cuab yeej tsim los ntawm cov khoom.

txoj cai ua haujlwm

Cov nplej nyoos ua ntej dhau los ntawm lub tshuab ntxhua khaub ncaws huab cua kom tshem tawm lub teeb pom kev zoo, impurities loj, thiab me me impurities. Tom qab ntawd nws dhau los ntawm cov khoom sib nqus sib nqus, lub destoner, thiab lub pycnometer kom tshem tawm cov impurities xws li av, pob zeb, thiab mildewed nplej, thiab ces nkag mus rau hauv lub tshuab polishing rau kev sib txhuam. Ua kom nws ci ntsa iab, tom qab ntawd nkag mus rau kev muab qhab nia thiab tshuaj ntsuam rau hauv cov khoom loj, nruab nrab thiab me me, thiab thaum kawg ua kom muaj nuj nqis ntim raws li kev ntim khoom sib txawv.

Khoom zoo

1. PLC tsis siv neeg tswj thiab tsis siv neeg lub tswb nrov pab txhawb cov neeg siv khoom tswj tag nrho;

2. Cov khoom tseem ceeb raug xaiv los ntawm cov khoom lag luam hauv tsev thiab txawv teb chaws, thiab cov khoom siv ua haujlwm ruaj khov;

3. Muaj cov txheej txheem tshem tawm cov plua plav tag nrho los sau thiab ua cov plua plav hauv nruab nrab, ua kom huv thiab tiv thaiv ib puag ncig;

4. Txhua qhov ntawm cov qauv yog txuas nrog bolts kom txo tau cov nqi kev teeb tsa thiab kev thauj mus los;

5. Cov txheej txheem tsim khoom tuaj yeem ua tiav raws li qhov chaw, thiab cov khoom siv layout tuaj yeem pab tswj xyuas thiab kho.

Nws yog tsim rau kev ua ntawm ntau yam nplej thiab legumes xws li mung taum, liab adzuki taum, thiab taum raum.

Post lub sij hawm: Jan-08-2024