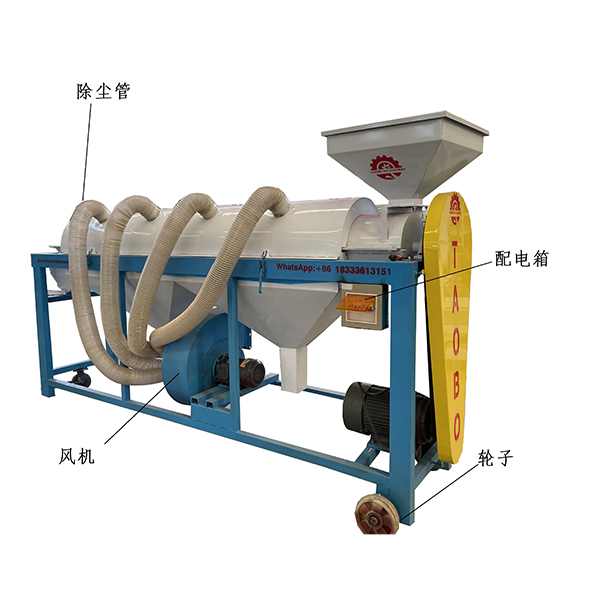

taum liab, mung taum, soybean polishing tshuab rau tu muddy ntsej muag / taum grain polishing tshuab yog ib hom tshiab ntawm cov nplej tu thiab ua cov khoom siv yooj yim. Cov khoom siv sib xyaw ua ke ntau yam haujlwm xws li kev tshem tawm cov nplej, nplej polishing, thiab tshem tawm cov kab mob mildew. Tom qab rov ua haujlwm ua haujlwm, cov cuab yeej tau ua tiav cov yam ntxwv ntawm lub zog qis, ntim ntau lawm, kev ua haujlwm yooj yim, tsis muaj plua plav ntawm qhov chaw ua haujlwm, txav tau yooj yim, thiab cov nyhuv polishing zoo, thiab tau txais txiaj ntsig zoo los ntawm cov neeg siv cov nplej.

Grain polishing tshuab yog dav siv nyob rau hauv kev lag luam nplej, feem ntau yog rau deawning thiab polishing grain particles xws li taum, nplej, mov, mov, nplej thiab lwm yam industries nyob rau hauv noob ua, ua liaj ua teb thiab sideline khoom ua, thiab lwm yam, tshwj xeeb tshaj yog rau taum uas tau yeej ib txwm ntxuav. Cov nplej ua haujlwm zoo dua. Cov khoom lag luam ua tiav los ntawm cov cuab yeej no yog ci thiab meej, nrog kev ua tiav zoo, thiab cov khoom zoo yog txhim kho ntxiv.

1. Cov qauv no siv lub tshuab vibration raws li qhov kev vibration, qhov xav tau amplitude thiab vibration kev taw qhia lub kaum sab xis tuaj yeem kho tau yooj yim thiab raug, thiab nws tsis ntshai los nag; nws yog resistant rau kub thiab tsis kub, thiab muaj zog kev ntseeg.

2. Lub hoist mechanism yog compact, saj zawg zog nyob rau hauv configuration, yooj yim los tswj, thiab yuav kho tau thiab txav tau zoo dua hloov mus rau txawv chaw ua hauj lwm.

3. Kev xaiv ob-lub tog raj kheej elevator tuaj yeem tiv thaiv cov qoob loo poob los ntawm kev nkag mus rau lub log tsav, yog li txo qis extrusion thiab crushing.

4. Txhua lub luj tshib tau txais cov cuab yeej siv cuab yeej los tshem tawm cov vuam tsis xws luag, nrog kev sib khi zoo, hnav tsis kam thiab ua haujlwm ntev;

5. Tsim nyog cyclone plua plav tshem tawm qauv, thiab kev teeb tsa ntawm lub kaw ntom nti cov plua plav tawm valve kom txo tau cov pa tawm, txhim kho cov plua plav tshem tawm, thiab ua kom lub chaw ua haujlwm huv thiab zoo ib puag ncig.

6. Cov khoom siv tu cov roj hmab tau xaiv muaj cov yam ntxwv ntawm cov elasticity siab, tiv taus txias thiab kev laus. Nws tseem tuaj yeem ntxuav tau zoo thaum lub caij ntuj no thiab txhim kho permeability ntawm lub vijtsam.

7.Nws muaj ntau yam kev siv thiab tuaj yeem siv rau hauv kev ua cov noob thiab kev ua liaj ua teb thiab cov khoom lag luam kev lag luam. Nws muaj cov txiaj ntsig zoo ntawm cov noob qoob loo, cov ntoo ntoo ntoo, cov noob qoob loo, cov noob qoob loo, cov nplej ntau yam thiab cov nplej ua lag luam, thiab lwm yam. Export ua cov khoom ua liaj ua teb thiab sab nrauv (xws li liab Adzuki taum, soybeans, mung taum, sunflower noob, melon noob, thiab lwm yam) kuj siv tau.

Lub hom phiaj tseem ceeb ntawm lub tshuab polishing:

1: Cov khoom siv awning ua ntej ua cov noob,

2: Tshem tawm cov plua plav ntawm qhov chaw ntawm tag nrho cov nplej

3: Ua kom lub ntsej muag tiav thiab ci ntsa iab ntawm tag nrho cov nplej

4: Tshem tawm mildew ntawm tag nrho cov nplej

Post lub sij hawm: Oct-26-2022